Click to learn more about lithium batteries==>>

Various lithium battery procurement customization==>>

In terms of its scope, battery management can be divided into two aspects: broad sense and narrow sense. The generalized battery management can involve the charging and load discharging of the battery, in order to improve the performance of the battery, coordinate charging and discharging, and adjust the charging and discharging speed under appropriate circumstances, which is equivalent to the power management and energy management part of a system. A typical application is the battery management of hybrid vehicles. Since the energy supply of the hybrid vehicle is not only the battery, but also other energy sources, the charging and discharging speed and energy supply ratio of the battery can be arranged according to the actual situation of the battery. In a narrow sense, battery management only manages various states and parameters of the battery, and provides necessary functions such as data communication, and does not involve charge management and discharge management. This is also more in line with the term “battery management”.

The charging of the battery is limited by the power supply capacity and voltage of the charger (machine), which belongs to the extension of the battery management and is not controlled by the battery management; similarly, the discharge of the battery is mainly affected by the size of the load, and the adjustment of the load size is generally at a higher level It is not adjusted by the battery management according to the situation of the battery itself. The battery management only monitors the state of the battery and the state of charge in the battery, and makes appropriate control adjustments to the battery and its internal components according to its state. The battery management does not control other components outside the battery, but only provides the data status notification function of communication. However, the battery management receives the control information of the upper-level main control module and makes necessary control responses. At present, the battery management system in the general sense refers to the concept of battery management in a narrow sense. The charging management is realized by the charger (machine), and its interface is generally realized by the battery voltage. The charger uses the battery voltage to determine whether to use constant current charging/constant voltage charging, trickle charging, floating charging, etc. Discharge management and load management are made necessary adjustments by the upper-level main control module of battery management according to the information provided by battery management.

As an important part of electric vehicles, the battery management system of electric vehicles plays an important role in real-time monitoring of battery status, optimal use of battery energy, prolonging battery life and ensuring battery safety. The battery management system has a great impact on the safe operation of the electric vehicle, the choice of the vehicle control strategy, the choice of the charging mode and the operating cost. The battery management system must reliably complete the real-time monitoring and fault diagnosis of the battery status during vehicle operation and charging, and inform the vehicle integrated controller or charger through the bus, so as to adopt a more reasonable control strategy. To achieve the purpose of using the battery effectively and efficiently.

The battery management system is closely integrated with the battery to detect the voltage, current and temperature of the battery in real time, and also performs leakage detection, thermal management, battery balance management, alarm reminder, calculation of remaining capacity and discharge power, and reporting of SOC and SOH status. It also controls the maximum output power according to the voltage, current and temperature of the battery to obtain the maximum mileage, and uses the algorithm to control the charger to charge the battery with the best current. Real-time communication with energy control system, vehicle display system, etc.

The power battery management system is essential during the charging process of the battery. The main function of the battery management system is to monitor the voltage, temperature and current of each single battery of the battery pack in real time during the charging process. Battery real-time and historical information. The battery management system is an important guarantee for the optimal and safe charging of the battery.

The battery pack is prone to problems during the charging process, mainly caused by the excessive consistency error of the battery. For this reason, in the past ten years, many experts and scholars at home and abroad, as well as manufacturers and users of batteries, have vigorously carried out research aimed at solving the harm caused by battery consistency errors, and developed a variety of For the battery management system, in order to meet the requirements of balancing the battery, the balancing methods developed include the shunt method, the cut-off method, the parallel method, the energy recovery method, the auxiliary charging method, and the single charging method.

However, there are few satisfactory results from theoretical analysis and practical application effects. This is not due to a problem with the electronics, but due to a problem with the concept of the battery management system and the battery management strategy. Therefore, the battery management system must be designed according to the scientific concept and adopt effective strategies. The recommended method is to monitor the voltage, temperature and current of each single battery in real time around the clock during charging, discharging and parking, and set the maximum charging voltage, minimum discharging voltage, maximum and The threshold value of the minimum operating temperature and the maximum current, when the voltage, temperature, and current of a battery pack exceed the limit, the regulation and alarm functions are activated. On the one hand, it is guaranteed that any single battery will not work beyond the limit. On the other hand, it is ensured to continue charging at a slightly smaller charging current until the total charging voltage and the minimum charging current reach the set value and the charging ends. The equalizing charging of the battery is automatically carried out during the regulated charging process.

At present, the main factors affecting the popularization and application of electric vehicles include the safety of power batteries and the cost of use. Extending the service life of the battery is one of the effective ways to reduce the cost of use. In order to ensure the good performance of the battery and prolong the service life of the battery, the battery must be managed and controlled reasonably and effectively. The battery management system can monitor the condition of the power battery in real time to ensure the normal operation of the electric vehicle.

At home and abroad, a lot of manpower and material resources have been invested to carry out extensive and in-depth research on the battery management system. Japan’s Aomori Industrial Research Center has been conducting research on the practical application of battery management systems since 1997; Villanova University and USNanocorp have cooperated for many years to predict various types of battery SOC (battery remaining power) based on fuzzy logic. ; Toyota, Honda and General Motors, etc. have included the battery management system into the focus of technology development. During the 10th Five-Year Period, my country set up major special research projects for electric vehicles, actively promoted the research, development and engineering application of battery management systems, and achieved a series of achievements and breakthroughs.

Compared with the electric motor, electric motor control technology and battery technology, the battery management system is not very mature. As one of the most critical technologies for electric vehicles, the battery management system has been greatly improved in recent years, and many aspects have entered the stage of practical application, but some parts are still not perfect, especially in the reliability of collected data and SOC estimation. Accuracy and safety management need to be further improved and improved.

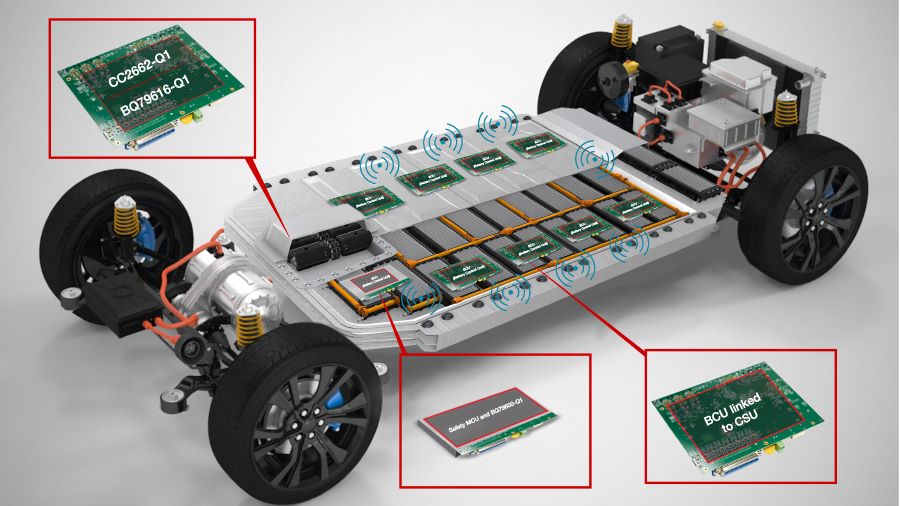

The battery management system must reliably complete the real-time monitoring and fault diagnosis of the battery status during vehicle operation and charging, and inform the electric vehicle controller or charger through the bus, so as to adopt a more reasonable control strategy. To achieve the purpose of using the battery effectively and efficiently. The battery management system adopts a distributed system structure. Each battery management system consists of a central control module (or host) and 10 battery monitoring and control modules (or slaves). The battery management system detection module is installed in the front panel of the battery box, and the battery management system main control module is installed in the high-voltage equipment compartment at the rear of the vehicle. The functions of the battery management system are as follows:

(1) Detection function, including detection of single battery voltage, temperature detection, detection of working current of battery pack, detection of insulation resistance, etc.

(2) Dynamic detection function, which dynamically detects the insulation resistance between the power battery and the chassis, and can display the change process of the insulation resistance on the panel.

(3) Estimation function of battery pack SOC.

(4) Cooling fan control function.

(5) Recording function, including the number of charging and discharging, and the number of charging and discharging of a single box of batteries, etc.

(6) Discreteness evaluation of single-box battery.

(7) Communication functions, including communication with on-board equipment to provide necessary battery data for vehicle control (CAN1); communication with on-board monitoring equipment to send battery information to panel display (CAN2); communication with chargers to safely realize battery Charge (CAN3).

(8) The battery balance maintenance function detects the temperature difference between the single batteries, and reaches a certain temperature difference, and gives instructions to carry out battery balance maintenance.

(9) Initialization function, the initialization of the battery management system is realized by a simple device, which can meet the needs of rapid battery replacement and reorganization of battery boxes.

(10) Fault detection and alarm functions, including battery fault analysis and online alarm, battery management system self-inspection and processing, when the battery management system fails, the system can perform self-inspection, control according to the requirements of the battery pack, and deal with it accordingly.

11) The basic protection functions of the battery management system include:

①Overvoltage protection function (OV). During charging (including braking energy recovery), when the charging voltage of any battery exceeds the set value, the charging voltage will automatically decrease to prevent the battery from being overcharged.

②Low voltage protection function (UV). During discharge, when the discharge voltage of any battery is lower than the set value, the discharge will be stopped to prevent the battery from over-discharging.

③High temperature protection function (OT). Whether it is charging or discharging or in the dormant state, when the temperature of any battery exceeds the set value, the battery thermal management system is activated to reduce the battery temperature. When the maximum temperature is exceeded, the circuit should be automatically cut off immediately.

④Low temperature protection function (UT). When charging, when the temperature of the battery is lower than the set value, the charging current will be automatically changed, generally reduced to 1/3 of the charging current; when discharging, when the temperature of the battery is lower than the set value, the battery thermal management system will be activated to improve the battery. temperature.

⑤Overcurrent protection function (OC). When charging and discharging, the current of the battery exceeds the set value, and the increase of the current is automatically limited.

⑥ Short circuit protection function (SC). When charging, discharging and in the dormant state of parking, the circuit will be automatically cut off when the battery is short-circuited.